Customer Challenge

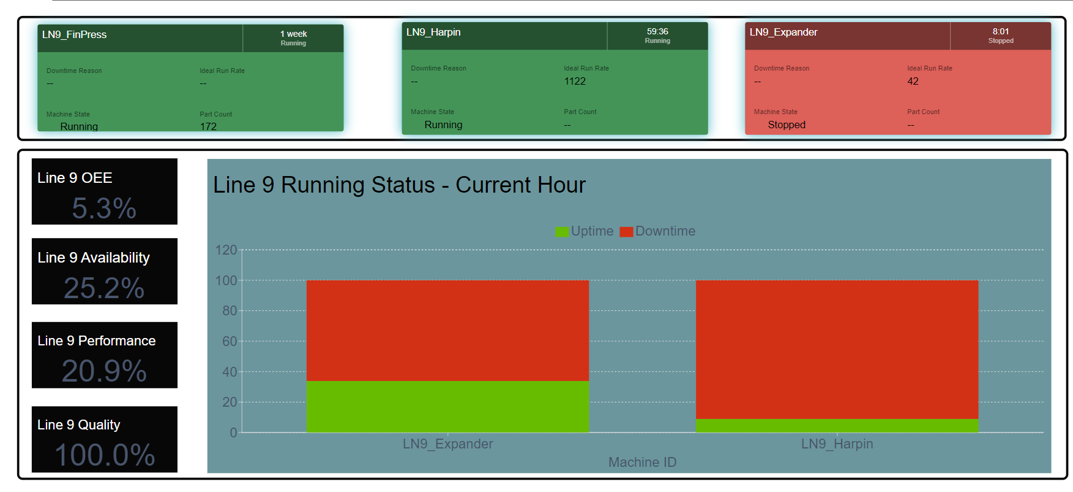

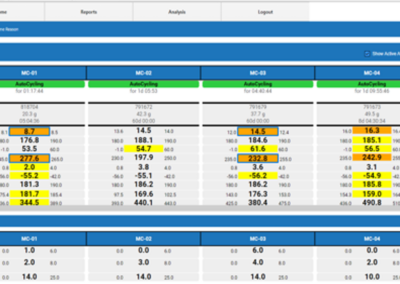

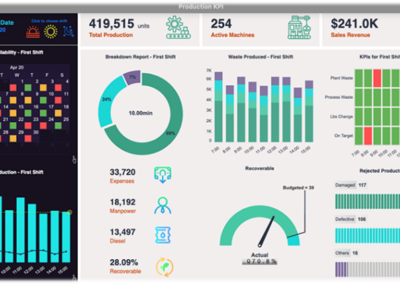

An HVAC manufacturing plant required a tool that allowed operators to track machine performance on the shop floor.

The goal was to enable management to oversee production through a user interface, which monitored key performance indicators (KPIs) and production line status.

Solution Approach

Utilized Tulip IIoT software to create and deploy an Operator user interface as part of a Production management application.

- Utilized Tulip Automations/Analytics providing rich data collected from remotely configured machines down to the manufacturing floor.

- Enabled production line reporting and KPI efficiency status of various pieces of equipment.

Results

Quality

By leveraging Tulip and tracking real-time performance metrics immediate detection of deviations from quality standards was ensured.

Productivity

Deployment of the operator user interface provided actionable insights, guiding operators in reducing unwanted downtime and improvement of overall equipment effectiveness.

Why Sandalwood?

Why Sandalwood?

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly.

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly. Why Sandalwood?

Why Sandalwood?

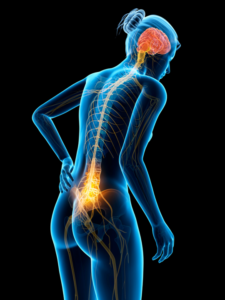

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.