Process Development |

New Process Development Leads to Methods and Throughput Improvements |

Client:

Military Truck Manufacturer

Objectives:

- Return costly outsourced work to plant

- Increase capacity by 50%

- Develop process content, sequence, times & flow

- Develop workstation tooling & layout requirements

- Develop operator instructions & work flow diagrams

- Develop material handling layout & operations

Project Description:

Increased capacity and improved cost were required to produce product orders in the time required by the client.

Sandalwood provided a multi-disciplined engineering team to work with the client in evaluating product content, methods, labor and equipment requirements.

A new manufacturing layout was developed for an existing warehouse facility. Operations layouts and assignments were developed incorporating material handling requirements, operator instructions and work flow diagrams. Material handling operations and equipment were developed for flexible material flow. New process equipment and tools were designed, purchased and implemented to provide improved throughput capability.

Results:

- Capacity increased by 50%

- Costly outsourced operations returned to in-plant operations

- Assembly line process method installed to improve product flow and throughput

- In-station process control system updated to assure a complete, high-quality assembly process

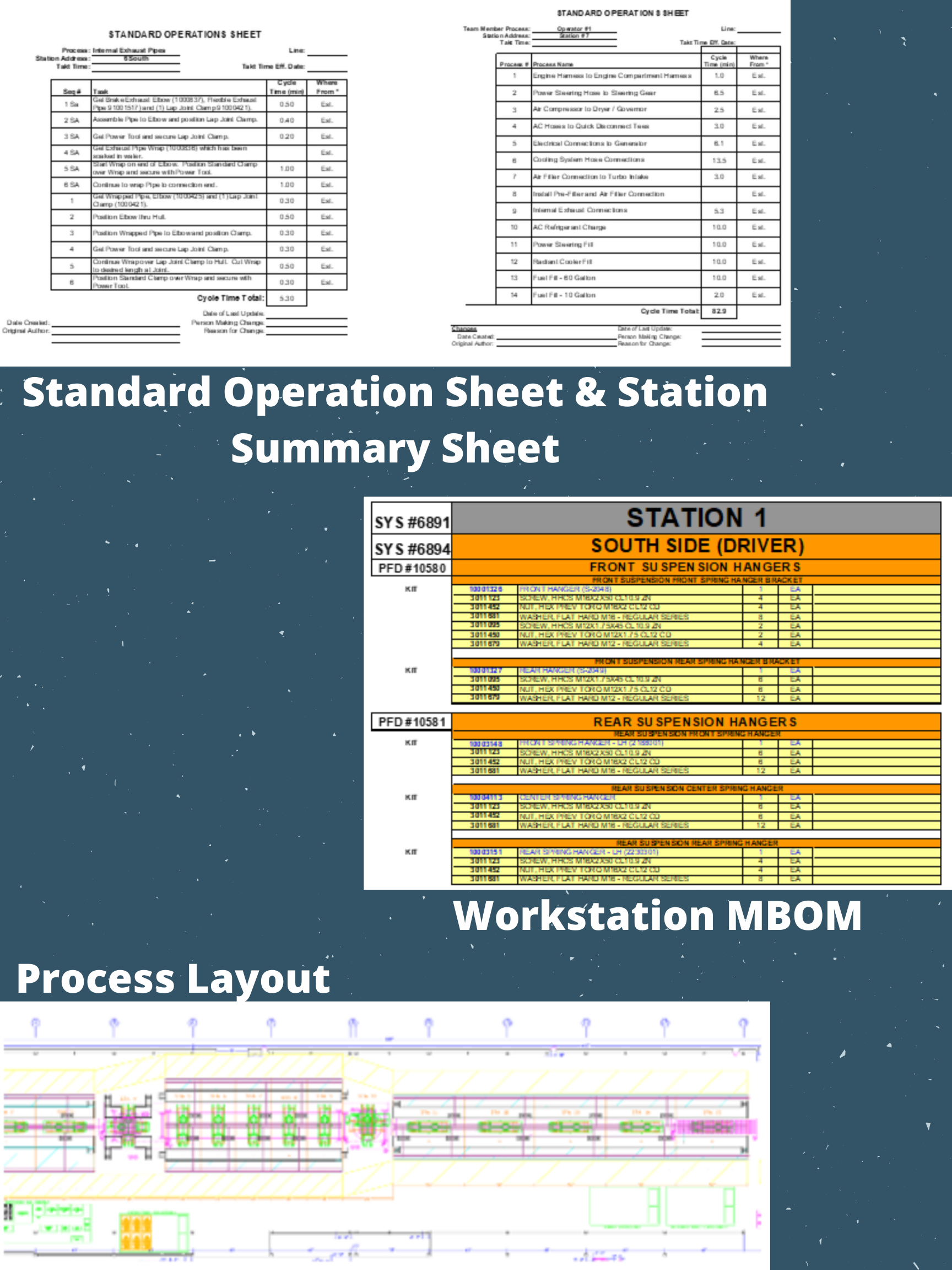

Standard Operation Sheet, Station Summary Sheet, Workstation MBOM and Process Layout

Related Case Studies

Why Sandalwood?

Why Sandalwood?

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly.

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly. Why Sandalwood?

Why Sandalwood?

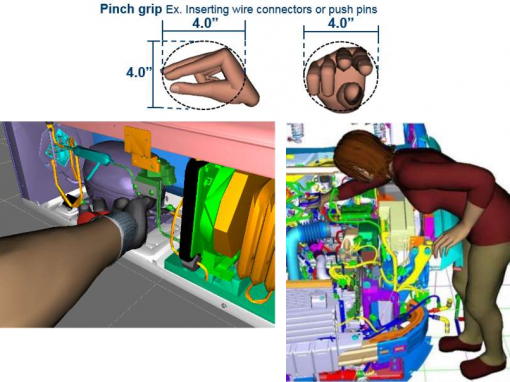

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.