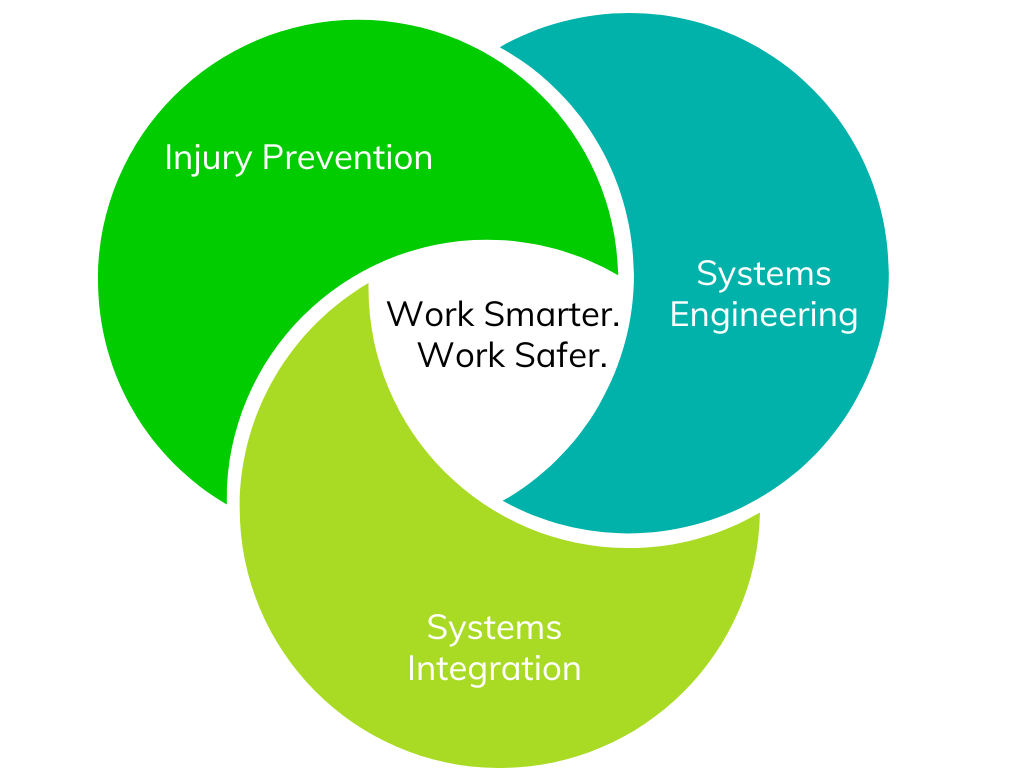

Sandalwood designs and executes strategic programs for manufacturers which reduce work-related risks to quality, productivity, and employee health.

injury prevention

Sandalwood believes that a robust manufacturing facility requires careful consideration of the interaction between process, equipment and the human. Our ergonomics and health and safety professionals understand the human response to physical and cognitive work demands.

systems engineering

Our experienced engineering team employs data driven process analysis, project and supply chain management to create and implement effective solutions to help optimize our customers’ products and processes.

systems integration

The Sandalwood Systems Integration Group offers tailored services for manufacturers on flexible arrangements, including dedicated, part-time, project, or support contracts. Collaborating closely with Change Agents and Operational Technology / Information Technology teams, we strive to enhance companies’ digital capabilities efficiently, maximizing resource utilization for optimal results.

Why Sandalwood?

Why Sandalwood?

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly.

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly. Why Sandalwood?

Why Sandalwood?

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.