Reducing the risk of injury in the workplace is a common goal of all who are involved with workplace health and safety. Typically these efforts involve making some sort of change which results in a reduction of an individual’s exposure to known or suspected injury risk factors. This is a good thing, for if you decrease exposure, you decrease risk.

See the full article below to learn just how tissues get damaged, and how this understanding leads to effective changes in the workplace to reduce injury.

—

Understanding the mechanism of how tissues get injured (e.g. muscles, tendons, ligaments) provides a foundation for better understanding risk factors which permits you to put forth better, more effective counter measures in the workplace.

So, how do tissues get injured? Tissue injury occurs when the tissue experiences an applied force that is greater than the tissue’s tolerance. Mathematically, this mechanism can be expressed as:

Applied Force > Tissue Tolerance

There are three very exciting things about this mechanism. The first is that it applies to all tissues (not just muscles, ligaments and tendons). Secondly, it applies to all injuries. And finally, it provides us three possible approaches to preventing tissue injury: a) decreasing the applied force, b) increasing the tissue tolerance, or c) some combination of a) and b).

But before we start thinking about possible approaches to the prevention of tissue injury, we need to explore the applied load and tissue tolerance relationship a little bit further so that we better understand the Modes of Tissue Injury.

Modes of Tissue Injury

High Force Injury

This type of injury is associated with a tissue experiencing a single high force event (e.g. slip, trip, fall, impact with, struck by). You can illustrate this type of injury by using some popsicle sticks and performing the following demonstrations.

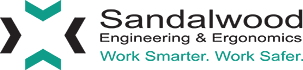

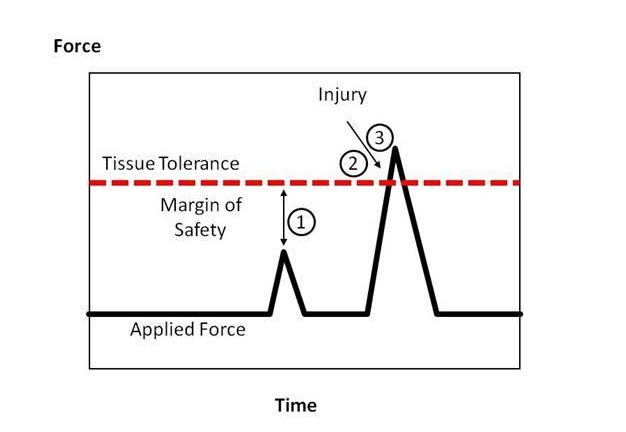

Demonstration #1: Hold the ends of a Popsicle stick (the tissue) between the thumb and forefinger on each hand. If you slowly apply a bit of force with your thumbs you can put a slight bend in the Popsicle stick. Release the force and the Popsicle stick returns to its original shape. Now, it is really important to observe here that “nothing happened” to the Popsicle stick! This result is identified by the circled 1 in Figure 1. Releasing the applied force (solid line) before the (tissue) tolerance level (dashed line) of the Popsicle stick was reached created a “safety margin” and no tissue injury occurred, which is our desired outcome in the workplace!

Demonstration #2: This is similar to Demonstration #1 but instead of slowly applying a small force, you increase the force until the popsicle stick cracks. Congratulations, you’ve now created a tissue injury! Note that the tissue can still bear a load, as it hasn’t been completely ruptured (separated) , but as a result of the injury it certainly cannot return to its original shape. This result is identified by the circled 2 in Figure 1. The moment the applied force (solid line) reached the (tissue) tolerance level (dashed line) the injury occurred.

Demonstration #3: You’ll need another popsicle stick and this time you’ll apply a large force very quickly so that you can completely break the tissue into two pieces. This result is identified by the circled 3 in Figure 1. The moment the applied force (solid line) reached the (tissue) tolerance level (dashed line) the injury occurred. Note that although the magnitude of the injury produced in Demonstration 3 is more severe than in Demonstration 2, the mode of injury is still the same.

Putting it Into Perspective:

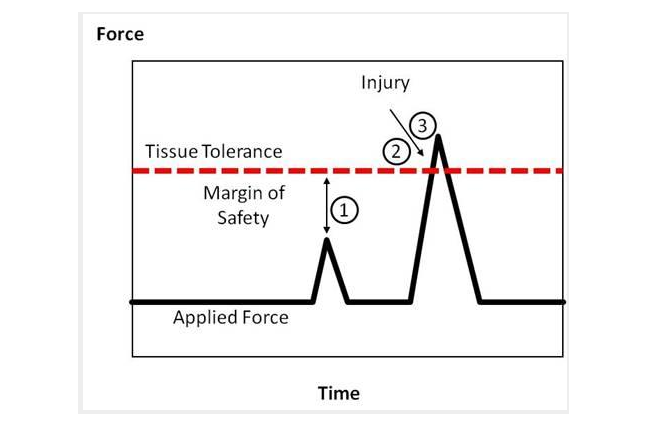

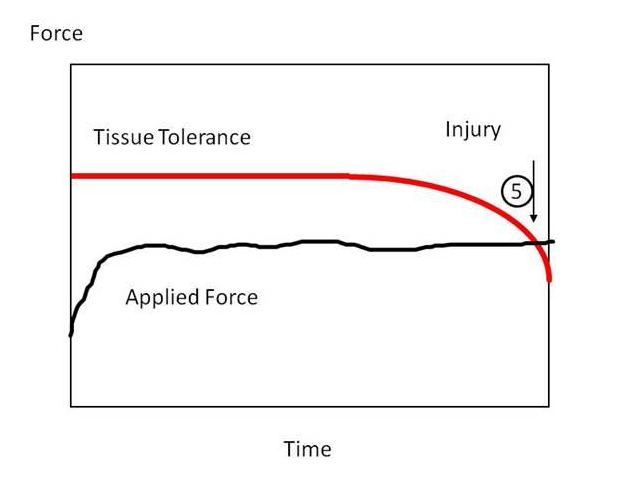

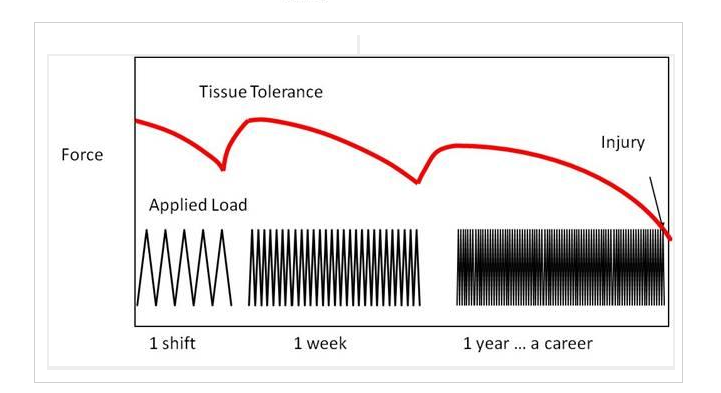

So how do Popsicle sticks, coat hangers and silly putty relate to the real, working world? Many of us have heard an injured worker exclaim, “I’ve done this my entire life without injury, why would I get hurt now?” One of the big advantages that humans have, unlike the inanimate objects used in the demonstrations, is that over time we can change the tissue tolerance level. This can occur as a result of rest (providing time for tissues to recover back to their starting level) or training (tissues become stronger so tolerance level increases). Also, humans have the ability to heal once a tissue becomes injured. However, a natural outcome of the aging process is that tissue tolerance decreases as we get older so that eventually our tissue tolerance levels will decrease compared to our “younger years”. Figure 4 uses all of these observations to help explain our injured workers situation.

After a single shift of work, the worker’s tissue tolerance has decreased but there is still a safety margin due to the applied load being less than the tissue tolerance. An evening of rest restores the tissue tolerance back to its original level. After a week of work we see the tissue tolerance has decreased even further but there is still a margin of safety present. A relaxing weekend restores the tissue tolerance but eventually it doesn’t return to its original level. Then, after a year or two, or perhaps well into a career, the tissue tolerance has decreased to a level where the applied load, the size of which hasn’t changed over this time period, is now at a point where it exceeds the tissue tolerance and an injury occurs!

Figure 4: An example of tissue injury produced over a career due to decreased tissue tolerance

Putting it Into Practice:

The next time you make a change in the workplace try to identify the effect the change will have on the safety margin for the tissues in the body part of concern. If the change is expected to increase the safety margin how will this be accomplished? Will, a) the tissue tolerance increase, or, b) the applied load decrease, or c) will it be a combination of the two?

Knowing how the change will specifically affect tissue injury will allow you to provide this information as further support for change and to explain the impact of the change to those involved. If your evaluation identifies that the change isn’t going to have an impact on either a) or b) then you should re-evaluate the proposed change for it appears that there is a good chance that it may not produce the desired outcome.

Why Sandalwood?

Why Sandalwood?

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly.

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly. Why Sandalwood?

Why Sandalwood?

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.