SCADA

Optimize Plant Floor Operations

Having real-time visibility and control of your plant floor operations is critical to quickly identifying and resolving production line issues, reducing unscheduled downtime, addressing quality issues, and managing part complexity.

Sandalwood can help evaluate the best systems for your purposes including matching budget to desired functionality, ease of integration, maintainability, and ability to grow as your operations grow.

Supervisory Control

Proper preparation and implementation of your SCADA system enables comprehensive monitoring, real-time data analysis, and automated process adjustments.

Reporting & Historians

Proper structure and harmonization ensure that your disparate data can be combined and reported effectively and coherently.

Enterprise Solutions

We have experience implementing from ERP level business planning and logistical functions, all with the end objective in mind; cohesive, smart, and connected systems.

Process Visualization

Today’s analytics and data visualization tools provide unprecedented capabilities to assess your data for process optimization.

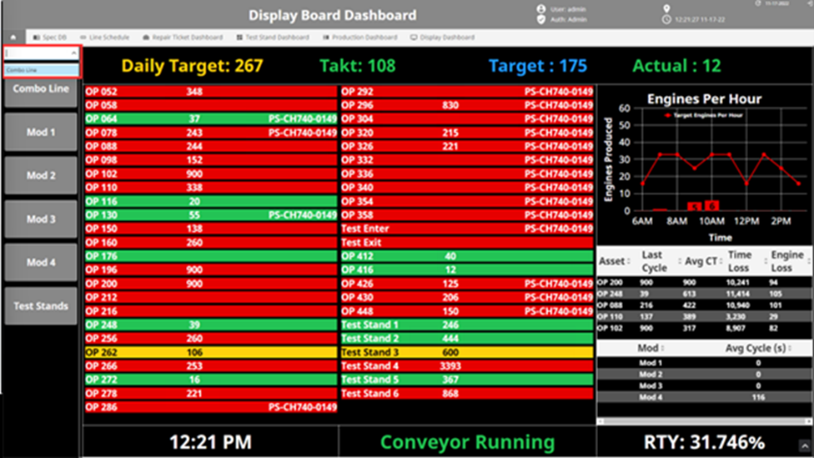

SCADA CASE STUDY HIGHLIGHT

Ignition Enables Phased Digital Transformation

Leveraging both Ignition’s Perspective and Vision components, a modular and scalable system was created to rapidly deploy templatized HMIs for machine control, collect available test and production data from the shop floor, and aggregate that information into useful production board displays, operator interfaces, production dashboards, and executive reports.

Still have questions about systems integration?

SCADA Resources

Case Studies

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Blog Posts

Advances in Ergonomics: Virtual and Augmented Reality

Through the use of XR technologies, we can assess how a human would interact with future designs in a true-to-scale environment. Watch this simulation – if we simply look at the assembly of the part, this will pass virtual checks and move forward to kick-off physical...

Reduction of Injuries Starts With Safety Design

Safety risk assessments allow you to be proactive in preventing injuries. Starting the risk assessment process at the design phase of a tool saves time throughout the buy-off process and improves engineering utilization. An all too prevalent problem with most tooling...

Why Sandalwood?

Why Sandalwood?

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly.

We are a one-stop-shop for launching job rotation for any employer from conception to implementation. Our experts tailor our services to meet the needs of our customers by collaborating with them throughout the entire process. We do not offer cookie cutter solutions for job rotation because the needs of employers vary significantly. Why Sandalwood?

Why Sandalwood?

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.

Sandalwood is pleased to offer solutions above and beyond the traditional ergonomic assessments. With an in-depth knowledge of various digital human modelling software suites, integration and adoption to your health and safety programs has never been easier. Sandalwood is experienced in ergonomic program design as well as industry leaders in digital human modelling services. We have a diverse team that is able the leverage the results from the digital human model to provide in depth risk assessments of future designs and current state. Sandalwood is also able to pair these assessments with expertise and provide guidance on the best solution for you. Sandalwood is also on the forefront of emerging technologies and able to integrate Motion capture, Wearables, and extended or virtual reality into your ergonomic program.